According to a new study prepared for Forest & Wood Products Australia by strategic research firm Pollinate and the University of Canberra — Workplaces: Wellness + Wood = Productivity; natural wood is the key to increased workplace productivity.

The study reveals that adding natural elements, such as wood surfaces in the work environment, is a major driver of enhanced feelings of wellbeing, higher productivity and workplace satisfaction.

These findings provide growing evidence supporting the business case for biophilia that was first popularised by biologist and author Edward Wilson — the principle that explains, “Humans have an innate tendency to seek connections with nature and other forms of life.”

The study unpacks findings from a survey of 1,000 indoor Australian workers — less than 47% reported having access to natural light, 38% were surrounded by indoor plants, 26% are unable to see any natural-looking wooden surfaces and 46% spending less than an hour outdoors during the working week.

Dr Jacki Schirmer, an associate professor of health research at the University of Canberra, told the Green Cities audience,

“We know it’s good for us to spend time outdoors interacting with nature, but with people spending so much time indoors, there’s increasing recognition of the potential benefits of bringing nature into the workplace and the home.”

“The academic world is becoming increasingly switched on to biophilia as an area warranting real research and attention, and some engineering degrees are starting to include it as a subject. ”

“Importantly, wood is a particularly useful tool for bringing nature into the workplace in situations where it is not feasible to retro-fit other changes, such as increased natural light.”

The report indicated that 82% of workers who were employed in places with eight or more wood surfaces had higher personal productivity, mood, concentration, clarity, confidence and optimism — and were more likely to find their workplaces relaxing, calming, natural-feeling, inviting and energising, compared to 53% of workers with no wooden surfaces present in their work environment.

This research report resonates with studies that have suggested that more wood and other natural materials in educational environments can lead to similar results, with indicators being higher academic marks, positive social interactions and better student behaviour. Studies have also demonstrated a profound impact on hospital patients surrounded by natural elements; from lowering blood pressure and heart rate to alleviating stress.

Wood is naturally an absorbent material and when water soaks into it, it causes permanent damage.

A steam mop by its very nature uses water heated to 120 degrees or over 200 degrees on some models.

Steam mops put heat and excessive water on the floors; which soaks into the wood grains and causes it to expand, discolour and warp.

Flooring manufacturers and other professionals caution that steam can cause damage to both solid and engineered flooring:

- Steam is able to get down into the tiniest cracks and crevices and soak into the unfinished wood below the surface. The presence of lingering moisture can lead to problems in the future.

- Where a wax or varnish finish is present, the use of a high-temperature steam mop could ruin the finish and damage the wood itself.

- Newly sealed wood floors can be affected by steam as well because there might be missed spots in the sealant, especially the seams between the boards.

- Instances where planks are worn and areas on them may be missing finish, steam hydrates quickly and moisten the wood; causing dark and unsightly blotches of water-stained wood.

- When moisture is introduced at a deep level within the floorboard, it causes the wood to swell and press against each other. The edges can curl upward, and result in what is known as cupping. While this may abate somewhat when the wood dries out, the floor never returns to its original condition.

How to clean wood floors safely

Vacuuming and dust mopping regularly is essential to keep your wood floors clean.

Wipe up any liquid spills and dirt stains immediately to avoid water damage.

Avoid using vinegar or all-purpose cleaners on floorboards as this will dull the finish.

For households with pets and high foot traffic, a pH neutral cleaning solution should be mixed with water and applied using a damp microfiber cloth — never wet or soaking wet.

Always read your manufactures recommended cleaning instructions and ensure that you are aware of what you should and shouldn’t use.

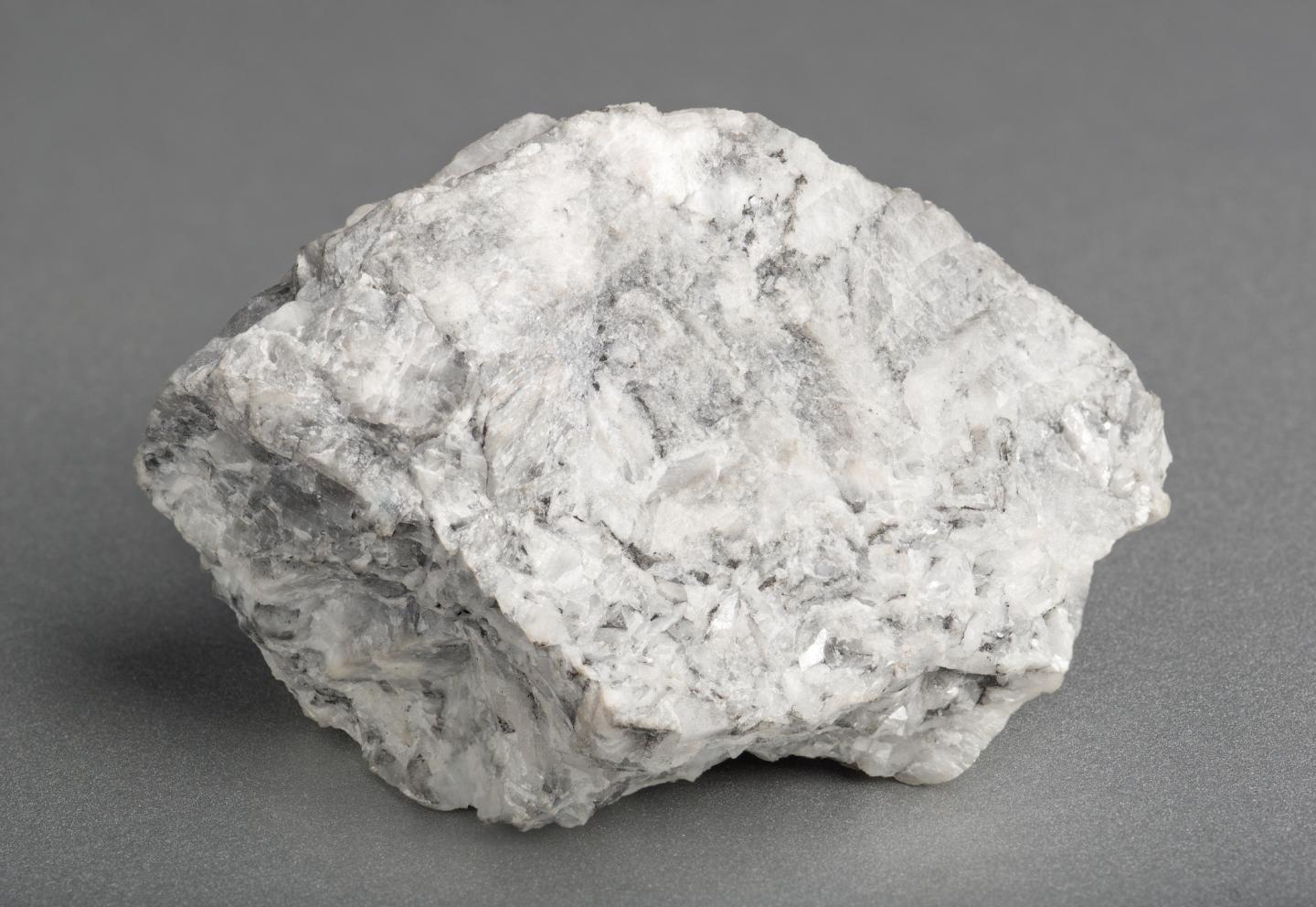

Magnesium carbonate naturally removes carbon dioxide pollution from the atmosphere, but the process is very slow one.

Carbon dioxide traps heat inside the atmosphere and keeps our planet warm — which means that the threat of global warming to life on earth still looms heavy.

Scientists have now developed a lab-made mineral that will suck CO2 and speed up the process.

This solution will rapidly create the mineral magnesite inexpensively and potentially at an industrial scale — and could slow or reverse the tide of climate change.

The first step was to analyse how a carbon dioxide-storing mineral called magnesite forms in nature, then figured out a solution in which they could speed up the process in the lab.

It takes hundreds of thousands of years for magnesite to form and grow; but in a Canadian lab, the team managed to speed up that process to just 72 days, using polystyrene microspheres as a catalyst to hasten production.

“Using microspheres means that we were able to speed up magnesite formation by orders of magnitude. This process takes place at room temperature, meaning that magnesite production is extremely energy efficient,“ an environmental geoscientist and professor Ian Power, from Trent University in Ontario, said in a statement.

The research is still in an experimental phase and the project is not a magic solution for global warming.

However, the team thinks the work might one day be used to improve carbon capture and storage technology.

“For now, we recognize that this is an experimental process, and will need to be scaled up before we can be sure that magnesite can be used in carbon sequestration (taking CO2 from the atmosphere and permanently storing it as magnesite),” Power said. “This depends on several variables, including the price of carbon and the refinement of the sequestration technology, but we now know that the science makes it doable”.

A carbon capture expert at Columbia University who was not part of the research, Peter Kelemen praised the “exciting” research in the statement, “The potential for accelerating the process is also important, potentially offering a benign and relatively inexpensive route to carbon storage, and perhaps even direct CO2 removal from the air”.

Ateliereen Architecten have devised the way up to the viewing platform at De Onlanden located southwest of the city of Groningen; with a proposed metal and wood configuration of a resistant, permeable and playful structure.

The observation tower extends 5 metres above the trees and offers views over the 3,000 hectares of natural landscape in the open countryside; recognizable, but appropriate to the environment.

A unique construction from what the Dutch architectural firm is known for; De Onlanden is easily assembled from screw and bolts — offering an expressive shape that turns not only the lookout point at the very top into a spatial adventure, but also the way up to it.

Instead of focusing on the lookout point, the road to it is designed as an experience.

Visitors climbing upwards arrive at the first view of about 9 meters, then a second intermediary platform at 20 metres high to view the “new nature” of De Onlanden.

On reaching the top, at an altitude of about 25 meters, they are rewarded with panoramic views of the natural de Onlanden landscape.

Designed and constructed as a single continuing shape; the large triangular wooden slats cover the sides and bottom of the stairs. This adds an air of playfulness, turning the structure from an otherwise boring tower into a whimsical, lively one.

Images: Ateliereen Architecten

The New & Reclaimed Flooring Company is launching a new showroom which will be housed in our flag workshop in Cheshire. Our new showroom will be geared up to service the leading creatives and design professionals in Manchester and Northern England.

The Cheshire showroom will offer you a comprehensive look inside our workshop and showcase our production and colouring process.

We will be delighted to welcome you and guide you through your ideas, designs and flooring requirements. Feel free to come in for a chat and spend time getting to know each of our floors on display; from bespoke finishes to the characteristics and quirks of our reclaimed floors.

Visit Our Cheshire Showroom

Unit 3 Hammond Trade Centre

Hammond Avenue

Stockport

Cheshire

SK41PQ

Norway is set to break the record for the tallest timber structure, which sits on the edge of a river in the small town of Brumunddal, an hour and a half drive north of Oslo.

Designed by Voll Arkitekter, the construction began in early September 2017 and is due completion in March 2019.

Mjøstårnet, named after its neighbourhood and Norway’s largest lake will reach 80 metres high, and stands 30 metres higher than what is today considered the world’s tallest timber building.

The 18 story high-rise building will include apartments, a hotel, offices, restaurant, communal areas and a 4,700-square-meter swimming hall.

Arthur Buchardt, investor and contracting client, has dubbed the construction “the closest we come to a skyscraper in timber” and believes “Mjøstårnet sets new standards for timber constructions”.

Timber used to construct the tower and the swimming pool area will be sourced from local spruce forests by Moelven, a Mjøsa-local Scandinavian industrial group.

Timber structures are becoming increasingly popular, and its ability to create skyscrapers is a benchmark for sustainable construction.

“A project group established by Norwegian road authorities investigated the possibility of building the world’s longest timber bridge across Lake Mjøsa. Their studies show that building with wood instead of concrete can reduce CO2 emissions by up to 30 percent,” said Buchardt.

The construction of Mjøstårnet hopes to inspire more large wood structures. “Through Mjøstårnet we demonstrate that it is possible to construct large, complex wooden buildings. The planned construction of the Norwegian Government quarter can become a wooden landmark internationally. I want to help convey an important message with this project. To build with wood is to contribute to the world breathing better.”

The lightweight property of the timber frame can sway up to 140 millimetres at the top when faced with strong winds of the region, which presents a challenge in the construction. A concrete floor slab will be used on the seven top floors to increase the weight towards the top and slow down the swaying. The building will also be anchored into the ground with piles up to 50 meters deep.

Images: Moelven Limtre (http://www.moelven.com)

Wood floors remain the most sought-after flooring material because of their authentic, elegant and timeless appearance.

We are pleased to provide answers to some of the most frequently asked questions about Wood flooring.

What are the benefits of Wood flooring?

- They offer an elegant and timeless look that never goes out of style.

- They also enable a look of spaciousness and lend a warm and authentic feel wherever they’re installed.

- Wood flooring offers a variety of appearances; from grain patterns to colours, stains and species.

- The floors are easy to clean as they do not accumulate a lot of dirt, dust and debris.

- Wood floors have long-term durability and can last for generations.

- They are a great long-term investment and can increase the value of your property.

- Properly installed wood floors increase and improve acoustics in the room; suitable for music rooms and concert halls.

- A healthy floor choice for allergy sufferers.

Are Wood floors good for homes with pets?

Wood floors are relatively easy to clean and maintain and can live in harmony with pets. However, they are vulnerable to scratches — hence choosing a harder species of wood makes it possible to enjoy your gorgeous floor without stressing about your pets.

A rustic or distressed finish is particularly a good option since it easily hides signs of everyday wear and tear. Alternatively, you may want to select wood flooring with a lighter colour and lower gloss level to help hide additional marks that may occur.

Can I use solid wood with underfloor heating?

Can I expect my wood floor to have colour variations?

Wood is a natural material, each plank features unique details and therefore, you should expect there will be natural colour variations. Most people love these slight variations for added character and charm that they offer. The higher grade of wood flooring tends to feature a more uniform colour and minimal character marks whilst a lower grade of flooring contains distinct variations in colour tone.

I have engineered wood flooring, can they be refinished?

Engineered woods have a thin veneer compared to solid wood. About 75% of engineered floors can be refinished — and the quality and thickness of the veneer layer is the major factor contributing to this. Premium collections have a thicker wear layer which can be sanded and refinished once, some up to 5 times. 0.6 mm thinner wear layer can only be recoated and cannot be sanded and refinished once they get worn.

Can wood flooring be installed over ceramic tiles?

Is it safe to use hardwood flooring in a kitchen?

Wood is a natural product, high temperature and moisture level in the kitchen may cause it to contract and expand. In this case, engineered wood is your best option to avoid cupping and gapping.

Occasionally a kitchen may experience spills and stains, but if cleaned up promptly this will have little effect on your hardwood floors. It is equally important to stick to a maintenance routine and never allow water to stand upon the surface for any amount of time.

How do I stop my wood flooring from gapping?

Gapping is fairly normal during the winter season due to change in humidity of the room which causes wood to dry out and shrink. To combat the issue, use a humidifier during winter months to keep your home within the required temperature — as long as humidity level is above 45%. Depending on your wood selection, certain species tend to contract and expand more than others. Using an engineered wood floor will reduce the appearance of gapping as it is more dimensionally stable than solid wood. Click here for the best whole house humidifier

Can I put wood flooring over an existing floor?

In some instance, wood can be glued down over existing floors such as: laminate, vinyl, wood floors, and even some types of tile. The existing floor has to be relatively smooth, free of major imperfections and fully adhered to the sub-floor. It is important that the installer follows the manufacturers recommended installation procedures.

Can I install wood flooring over radiant heat?

It is generally recommended installing floating engineered wood floor over the radiant heated sub-floor, but the installation has to be done according to the manufacturer’s exact specifications.

Now in its fourth year, the Architecture Awards return in 2018 to reward the most outstanding projects and works conducted by the leading designers, engineers and visionaries, whose inspiring designs and structures shape the horizons of the industry.

We are thrilled to have received Build 2018 awards for Best Wood Flooring Designers — London and Best London Wood Flooring Projects: Hatcham Park Road — Chevron Oak.

Hatcham Park Road — Chevron Oak

As you can see, this beautiful private residence on Hatcham Park Road simply oozes understated elegance and style. The light colour of the Chevron Oak floors plus the clever use of natural light enhances the harmony and openness of the residence, and complements the client’s choice of furnishings and accessories.

Reclaimed Beam Oak is carefully re-sawn from ancient Reclaimed European oak beams into 10mm overlay planks which can be used to enhance the appearance of property. The stunning visual impact of its patina and texture complements any interior style; from contemporary to traditional, and becomes the talking point of any room

The wood itself is full of variations and tonal contrasts which makes the reclaimed oak very easy to work with. Once the floors are installed, they can be coloured in a variety of ways to accentuate their character. From cool natural tones using white pigmented hard wax oil to a deep tanned finish using dark hard wax oils or waxes — the result is an authentic and refined aesthetic.

Do you know the difference between unfinished and prefinished wood flooring?

Wood flooring is an investment; it’s something that you will see, live with and appreciate every day.

However exhausting as it may seem, taking the time to carefully choose the best flooring for your project is important and will save you a lot of future headaches.

The best choice is one which gets you the results you deserve from your time and money.

When installing wood flooring, you will have to decide whether to go for prefinished or unfinished floorboards.

Below, we look at the main differences benefits of unfinished and prefinished wood floors.

Prefinished Wood Flooring

As the name suggests, our prefinished wood flooring has been finished — sanded, treated and coated with hard wax oils before it is brought to your doorstep.

Because the finishing has been applied under a controlled environment, the finishing is less likely to be contaminated by dust, hair and other foreign particles.

Once the floorboards are installed, the work is done.

Advantages of Prefinished Wood Flooring

Time: When installing wood flooring, it’s important to consider the project time frame. Prefinished boards offer a faster installation process; and once the job is completed, you can walk on it and arrange your furniture on it immediately.

Specialized Colours: Our finishing methodologies involves specialised processes and compounds that are not available elsewhere. It won’t be possible to achieve the same appearance on-site.

Less Messy: When installing prefinished wood flooring, there are no worries about dust, toxic fumes or odour.

Durability: Factory-applied finishes are incredibly durable.

Guarantees: Often, prefinished floors come with finishing guarantee. At RFC, we offer a 20 long year guarantee for our finishes.

Unfinished Wood Flooring

Also referred to as “on-site finished,” unfinished wood flooring is raw (sometimes sanded-only) wood flooring that leaves the factory with no finishing or treatment; and needs to be finished/coloured on-site after installation.

Advantages of Unfinished Wood Flooring

Natural Appearance: Unfinished wood flooring has a natural warmth and authentic beauty that’s often loved by many homeowners.

Matching Existing Flooring: If your home has existing hardwood flooring in other rooms, adding unfinished wood flooring makes it easier to create the closest possible match. This also allows you the freedom to test the stains and colours on the unfinished wood to exactly match the existing floor.

Wood Species and Plank Widths: Specific plank widths, some reclaimed wood or unusual wood species are only available as unfinished flooring.

Inspired by the trees on the estate, Modern Tree House designed by Cape Town based architects Pieter Malan and Jan-Heyn Vorster of Malan Vorster, features a contemporary cabin-like, one bedroom hide-away.

Located in a small clearing amongst forest-like gardens in Constantia suburb of the South African capital, the structure is elevated by four round columns in order to maximise views from the highest portion of the site.

The “Paarman Treehouse” draws inspiration from the timber cabins of Horace Gifford, Louis Kahn, Carlo Scarpa and Kengo Kuma’s approach to spatial configuration and meticulous detailing.

Composed of four cylindrical wooden towers elevated on stilts; the rings built from laser-cut and folded Corten steel plate supports the timber floors beams.

Red cedar battens wrap the tree house, with generous gaps throughout the windows and tighter spacing to help create a perfect balance between the resident’s enjoyment of the views and privacy.

The architect left all elements untreated, and will express the passing of time as they weather naturally to tone with the surrounding trees.

The home is four stories high — the first floor contains the living spaces, patio, dining; a bedroom and bathroom on the second level and a spacious roof deck on the top.

The interior is accessible via a suspended wood and Corten steel ramp; with a plant room located at ground level below the building.

The interior is high-end, pure elegance set against the peculiar wood and iron structure that the architects have wrought.

Contemporary furnishings adorn the space, making this not only a comfortable home, but also a timeless escape.

Images: Mickey Hoyle (http://mickyhoyle.com/)